Best quality Sodium Stearate Chemical Formula – Lithium bromide 7550-35-8 for Air Humidity Regulator – Gentolex

Best quality Sodium Stearate Chemical Formula – Lithium bromide 7550-35-8 for Air Humidity Regulator – Gentolex Detail:

Product Detail

| Product name | Lithium bromide |

| CAS | 7550-35-8 |

| MF | BrLi |

| MW | 86.85 |

| EINECS | 231-439-8 |

| Melting point | 550 °C (lit.) |

| Boiling point | 1265 °C |

| Density | 1.57 g/mL at 25 °C |

| Flash point | 1265°C |

| Storage conditions | Inert atmosphere, Room Temperature |

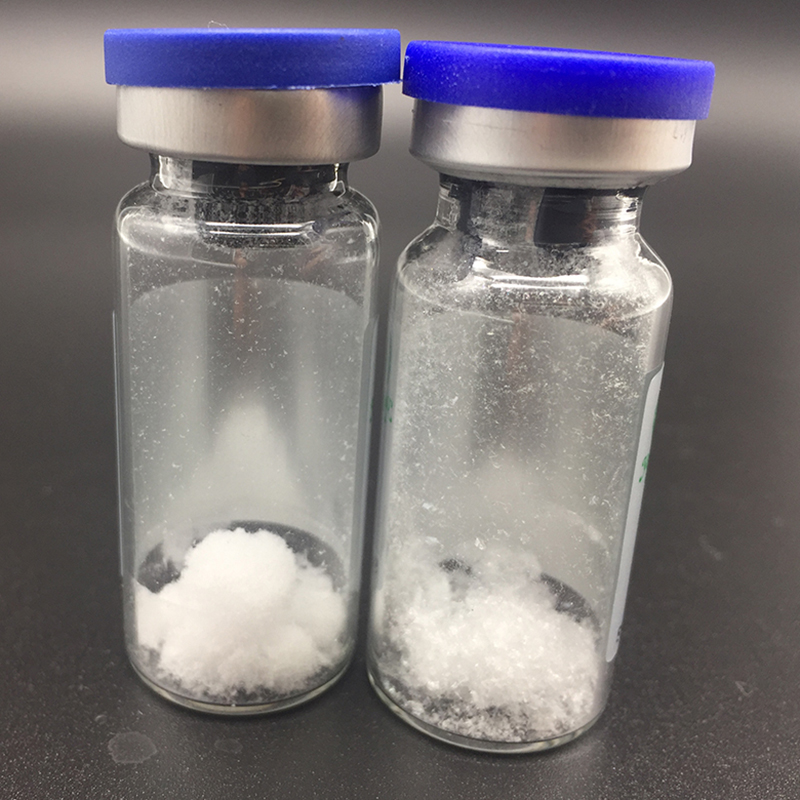

| Form | powder |

| Color | White |

| Specific gravity | 3.464 |

| Water solubility | 61 g/100 mL (25 º C) |

| Sensitivity | Hygroscopic |

| Package | 1 kg/kg or 25 kg/drum |

Function

It is an efficient water vapor absorbent and air humidity regulator. Lithium bromide with a concentration of 54% to 55% can be used as an absorption refrigerant. In organic chemistry, it is used as a hydrogen chloride remover and a leavening agent for organic fibers (such as wool, hair, etc.). Medically used as a hypnotic and sedative.

In addition, it is also used in the photosensitive industry, analytical chemistry and electrolytes and chemical reagents in some high-energy batteries, used as water vapor absorbents and air humidity regulators, can be used as absorption refrigerants, and also used in organic chemistry, medicine industry, photosensitive industry and other industries.

Chemical Properties

White cubic crystal or granular powder. Easily soluble in water, the solubility is 254g/100ml water (90℃); Soluble in ethanol and ether; slightly soluble in pyridine; Soluble in methanol, acetone, ethylene glycol and other organic solvents.

Related Categories

Inorganics; LITHIUMCOMPOUNDS; Essential Chemicals; Reagent Plus; Routine Reagents; Inorganic Salts; Lithium; Synthetic Reagents; Lithium Salts; Lithium Metaland Ceramic Science; Salts; Crystal Grade Inorganics; I-N,Purissp.a.; Purissp.a.; metalhalide; 3:Li; Beaded Materials; Chemical Synthesis; Crystal Grade Inorganics; Inorganic Salts; Lithium Salts; Materials Science; Metaland Ceramic Science; Synthetic Reagents.

QA

QA is responsible to evaluate and categorize the deviation into Major level, General level and Minor level. For all levels of deviations, the investigation to identify the root cause or potential cause is necessary. Investigation needs to be completed within 7 working days. The product impact assessment along with CAPA plan are also required after the investigation complete and root cause identified. The deviation is closed when the CAPA is implemented. All Level deviation should be approved by QA Manager. After implemented, effectiveness of CAPA is confirmed based on plan.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Best quality Sodium Stearate Chemical Formula – Lithium bromide 7550-35-8 for Air Humidity Regulator – Gentolex , The product will supply to all over the world, such as: Belgium, South Africa, Turkey, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.