Hot Sale for Acetate Periodic Table - 1-(4-METHOXYPHENYL)METHANAMINE – Gentolex

Hot Sale for Acetate Periodic Table - 1-(4-METHOXYPHENYL)METHANAMINE – Gentolex Detail:

Product Detail

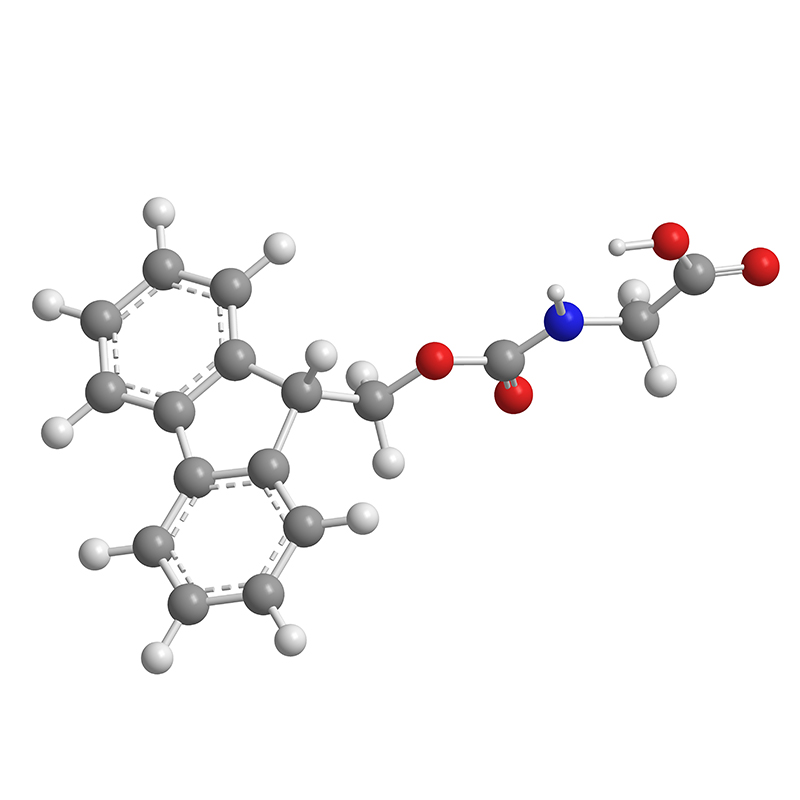

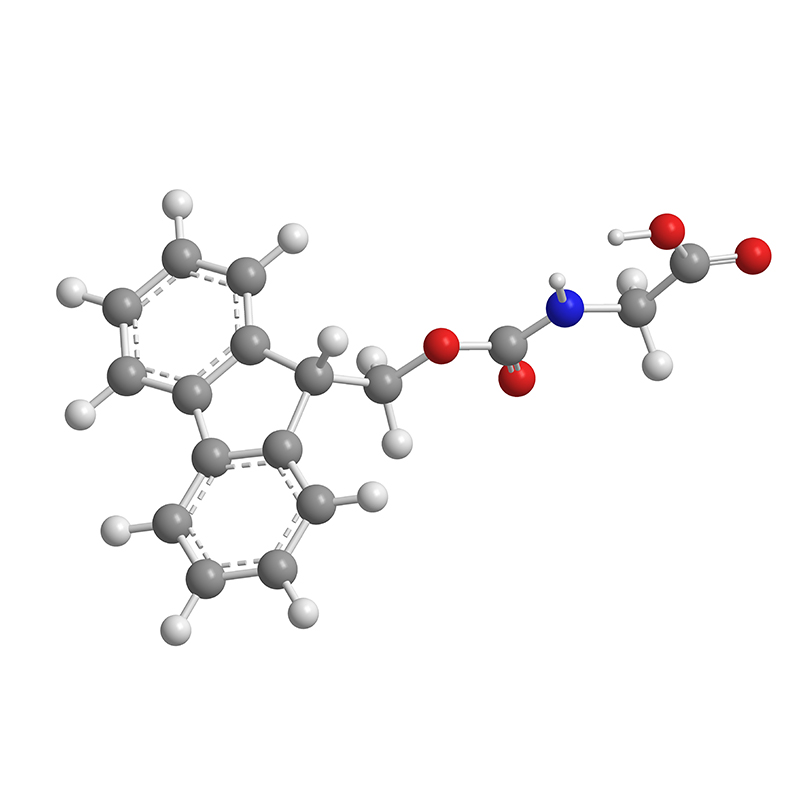

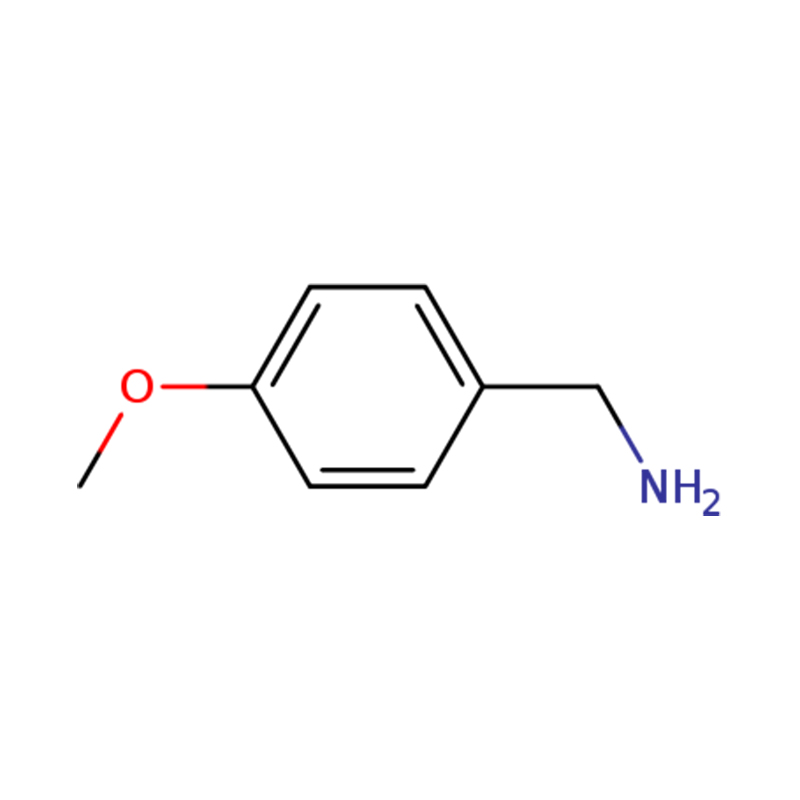

| CasNo | 2393-23-9 | DeliveryTime | within 10 days |

| Molecular | C8H11NO | Production Capacity | 1 Metric Ton/Day |

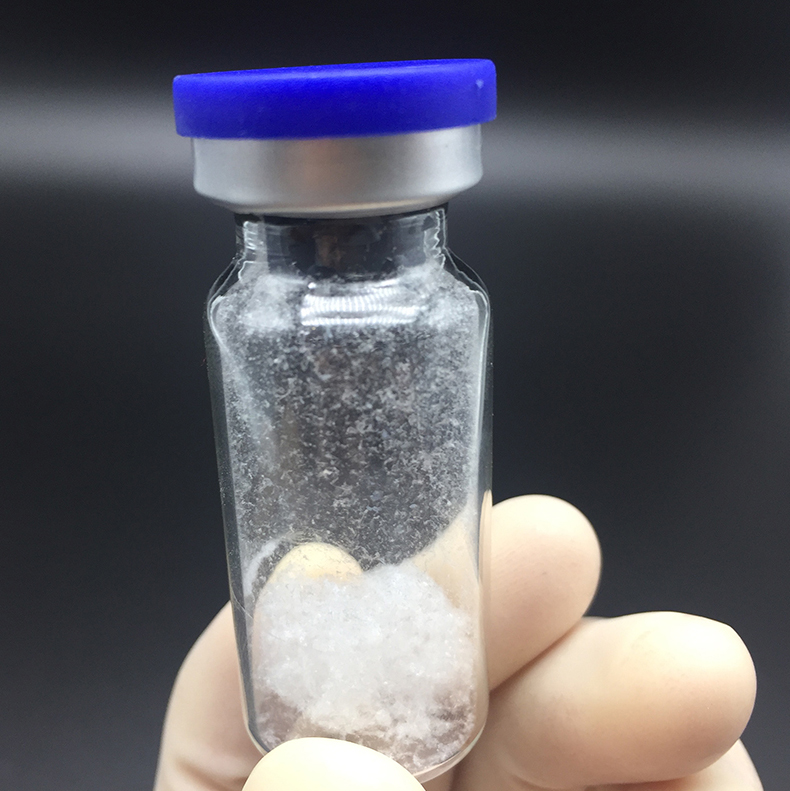

| Appearance | Clear,colorless to slightly yellow liquid | Purity | 99%min |

| Application | Pharmaceutical intermediates | Storage | Room temperature, dark, sealed |

| LimitNum | 1 Kilogram | Transportation | Air, Sea, Express. |

| Density | 1.05g/mLat25°C(lit.) | Boiling Point | 236-237°C(lit.) |

| Melting Ponit | -10°C | Refractive index | n20/D1.546(lit.) |

| Flash Point: | >230°F | Solubility | Highly soluble in water |

| Name | p-anisylamine or (4-methoxyphenyl)methanamine |

Synonyms

LABOTEST-BB LTBB000703; AKOS BBS-00003589; 4-AMINOMETHYL-ANISOLE; 4-METHOXYBENZYLAMINE; P-Methoxybenzylamine Hydrochloride173.64; 4-Methoxybenzylamine, 98+%; for Sparfloxacine; P-METHOXYBENZYLAMINE HYDROCHLORIDE

Application

It can be used for the synthesis of pharmaceutical intermediates. It is slightly harmful to water. Do not let undiluted or large quantities of products come into contact with groundwater, waterways or sewage systems. Without government permission, do not discharge materials into the surrounding environment to avoid oxides, acids. , air, carbon dioxide contact, keep the container sealed, put it in a tight extractor, and store in a cool, dry place.

QC Lab

An individual QC laboratory stands in the site where chemical, physical test, microbial test, stability study, instrument test such as IR, UV, HPLC, GC are performed for raw materials and finished products. The whole area is access controlled and well maintained with sufficient analytical instruments for intended testing purpose. All instruments are well labelled and appropriately calibrated.

QA

QA is responsible to evaluate and categorize the deviation into Major level, General level and Minor level. For all levels of deviations, the investigation to identify the root cause or potential cause is necessary. Investigation needs to be completed within 7 working days. The product impact assessment along with CAPA plan are also required after the investigation complete and root cause identified. The deviation is closed when the CAPA is implemented. All Level deviation should be approved by QA Manager. After implemented, effectiveness of CAPA is confirmed based on plan.

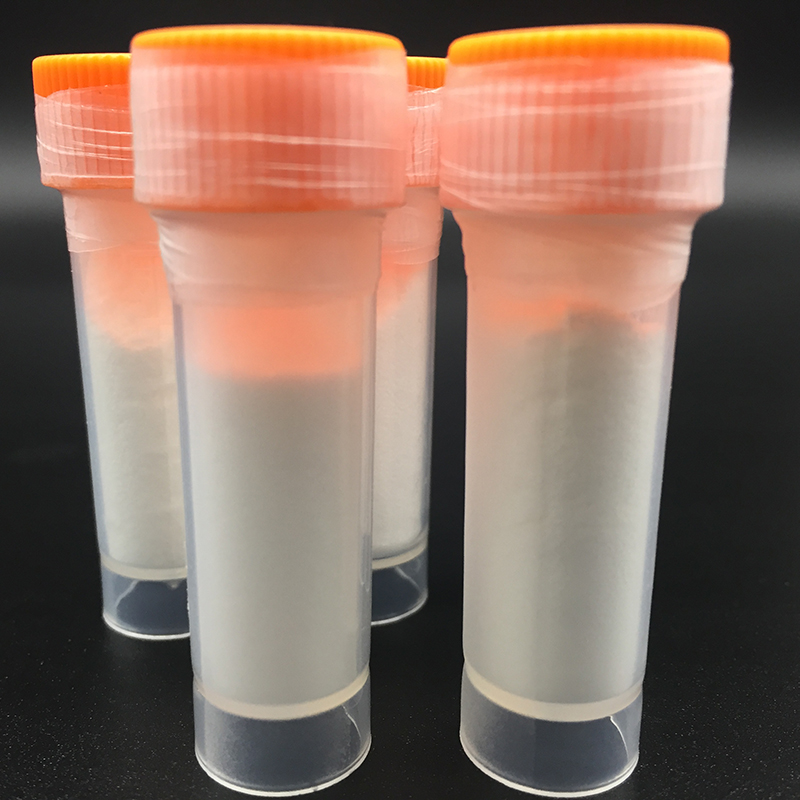

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Hot Sale for Acetate Periodic Table - 1-(4-METHOXYPHENYL)METHANAMINE – Gentolex , The product will supply to all over the world, such as: Mumbai, Saudi Arabia, Bahamas, Insisting over the high-quality generation line management and prospects guide provider, we have made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We're ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.