Sodium tetrachloropalladate 13820-53-6

Product Detail

| Name | Sodium tetrachloropalladate (II) |

| CAS number | 13820-53-6 |

| Molecular formula | Cl4NaPd- |

| Molecular weight | 271.21 |

| EINECS Number | 237-502-6 |

| Storage conditions | Inert atmosphere, Room Temperature |

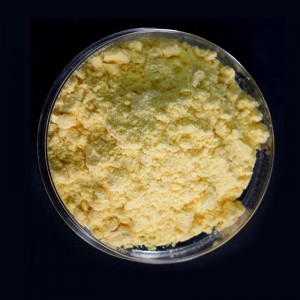

| Form | Powder and Granules Crystals |

| Color | Red-brown |

| Water solubility | SOLUBLE |

| Sensitivity | Hygroscopic |

| Hazard symbol (GHS) | GHS05, GHS07 |

| Hazard description | H290-H302-H318 |

| Precautionary Statements | P280f-P305+P351+P338 |

| Dangerous goods sign | Xi |

| Hazard category code | 36/38 |

Synonyms

Palladate,tetrachloro-,sodium,trihydrate;sodiumchloropalladate;tetrachloro-palladatedisodium;SODIUMTETRACHLOROPALLADATE(II)TRIHYDRATE,REDDISH-BROWNPWDR.;Palladate(2-),tetrachloro-,disodium,(SP-4-1)-;Sodiumtetrachloropalladate(II)trihydrate,99%;Sodiumtetrachloropalladate(II),99.9%(metalsbasis),Pd35.4%min;Sodiumtetrachloropalladate(II)hydrate,99.95%(metalsbasis),Pd30%

Application

Used to test the presence of gases as carbon monoxide

Sanitization

Sanitization of distribution system, including loop and storage tank is performed by Pasteurization. When Pasteurization sanitization is performed, the purified water in tank is heated up to 80°C and start to circulate by distribution system. The sanitization lasts 1 hour after reaching 80°C. Sanitization is performed every quarter. The purified water system sanitization logbook was checked with no excursion highlighted.

Purified Water

Purified water is used in production and equipment cleaning for API. Purified water is generated by city water, processed through pre-treatment (multi-media filter, softener, activated carbon filter, etc.) and reverse osmosis (RO), and then the purified water is stored in the tank. The water is constantly circulating at 25±2℃ with flow rate of 1.2m/s.

TOC and Conductivity

TOC and conductivity of main supply and return points are monitored periodically. TOC is monitored by QC on every week. Conductivity is monitored online and recorded by purified water station operator once every four hours. The conductivity is monitored at the primary RO, secondary RO, EDI and total return point of distribution system. The specification of purified water is in place and conforms to pre-defined specification which no more than 1.3 µs/cm at 25°C (USP). For main supply and return points, full test. is performed every week, for other using point in the circulating loop, full test is performed once every month. The full test includes characters, pH, nitrate, nitrite, ammonia, conductivity, TOC, non-volatile substances, heavy metals, microbial limits and bacterial endotoxin.